In today’s footwear, automotive, furniture, and consumer goods industries, brands are under growing pressure to cut carbon emissions and build more sustainable material strategies. Polyurethane (PU), a widely used material across these categories, has become a central focus for low-carbon innovation.

Two major pathways have emerged:

1. Recycled PU Systems

2. Bio-Based PU Systems

Both offer real environmental benefits, but the right choice depends on your brand’s CO₂ reduction goals, manufacturing setup, and long-term sustainability roadmap.

This guide will help you understand the differences, the science behind each option, and how to pick the right strategy for your business.

What Is Recycled PU?

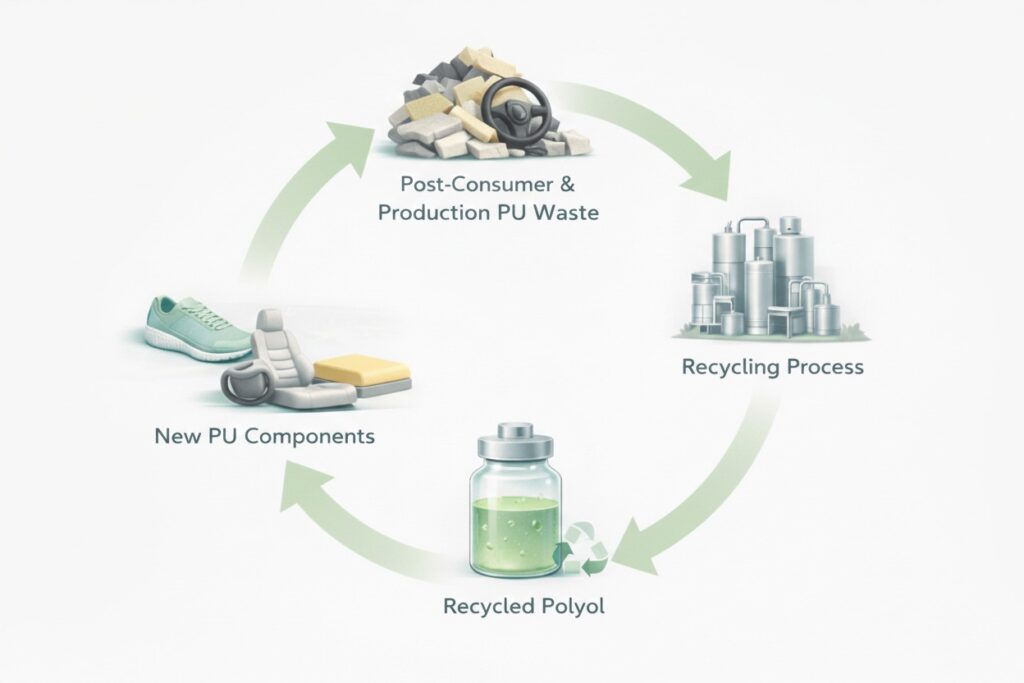

Recycled PU involves reusing post-industrial or post-consumer polyurethane waste and reprocessing it into usable polyols or functional filler systems. These recycled inputs replace virgin petroleum-based components.

How Recycled PU Helps Reduce CO₂

- Lower carbon footprint due to reduced extraction and processing of raw petroleum.

- Energy savings during manufacturing.

- Waste diversion keeps PU out of landfills and incinerators.

- Ideal for circularity initiatives within existing supply chains.

Where It Works Best

- Footwear insoles, midsoles, outsoles

- Automotive components

- Furniture cushions

- Industrial foams

Limitations to Know

- Slight variability in material consistency

- Requires proper waste collection and processing infrastructure

- Performance may not fully match virgin PU in certain high-stress or precision applications

What Is Bio-Based PU?

Bio-based PU replaces a percentage of petroleum-derived polyols with plant-based polyols sourced from castor oil, soy, sugarcane, palm, or algae.

How Bio-Based PU Helps Reduce CO₂

- Lower overall carbon footprint based on plant-derived raw materials

- Carbon sequestration during plant growth

- Stable raw material sourcing, especially for castor-based systems

- Helps brands achieve certifications such as USDA BioPreferred® andISCC+

Where It Works Best

- Premium footwear (sports, athleisure, comfort)

- Automotive interiors

- High-resilience cushioning

- Lifestyle products with sustainability claims

Limitations to Know

- Higher cost compared to standard PU

- Availability challenges for specific bio-polyols

- Needs R&D to optimize performance consistency

Recycled vs. Bio-Based PU: Side-by-Side Comparison

| Parameter | Recycled PU | Bio-Based PU |

| CO₂ Reduction Impact | Moderate–High, depending on recycled content | High, especially with high bio content |

| Cost | Low–Medium | Medium–High |

| Performance | Good for general applications | Excellent, suitable for performance industries |

| Circularity | Strong (supports closed-loop systems) | Moderate |

| Certifications | GRS, ISCC+ (recycled) | USDA, BioPreferred, ISCC+ |

| Best For | Budget-conscious, mass manufacturing | Premium, sustainability-driven brands |

How to Choose the Right PU Strategy for Your CO₂ Reduction Goals

1. If your priority is immediate CO₂ reduction at scale → Choose Recycled PU

- Delivers measurable CO₂ savings quickly

- Works seamlessly with existing moulds and processes

- Budget-friendly and scalable

2. If your brand targets premium sustainability claims → Choose Bio-Based PU

- Supports marketing claims like “Plant-Based”, “Bio-Derived”, and “Low-Carbon Material”

- Suitable for performance footwear and automotive interiors

3. If your long-term goal is TRUE circularity → Combine both

Hybrid strategies (e.g., recycled + bio-based blends) offer:

- Strong CO₂ reduction

- Improved circularity

- Balanced cost

- Better performance

This is the direction in which global leaders are already moving.

Focused Insight: What Indian and Asian Manufacturers Prefer

In markets like India, Vietnam, China, and Bangladesh:

- Recycled PU is scaling faster due to cost competitiveness

- Bio-based PU is growing rapidly in export-focused footwear and automotive brands

- Government incentives and global buyers are pushing for traceable and certified PU materials

Quick Answers for Buyers (FAQ)

✔️ Which PU option reduces the most CO₂?

Bio-based PU usually shows higher direct carbon reduction, but recycled PU provides overall system-wide carbon efficiency.

✔️ Is recycled PU cost efficient?

Yes. It is generally more cost-effective and easier to integrate.

✔️ Is bio-based PU good for performance shoes?

Absolutely. Its resilience, softness, and durability make it ideal for performance footwear.

✔️ Can brands use both strategies?

Yes, many leading brands use hybrid blends for optimised performance and sustainability.

The Future: Rymbal’s Low-Carbon PU Ecosystem

At Rymbal, we are engineering next-generation PU systems that help brands:

- Reduce CO₂ emissions

- Move toward circular manufacturing

- Improve durability & comfort

- Meet global sustainability standards

Our solutions include:

✔ Reprocessed & recycled PU systems

✔ Bio-based polyol systems

✔ Hybrid low-carbon PU systems

✔ Certified ISCC+ raw materials

✔ High-resilience, lightweight foams

If your brand is planning a sustainability roadmap for 2025–2030, choosing the right PU strategy is the first and most impactful step.

Ready to build your low-carbon PU strategy?

Let’s plan it together.

📩 info@rymbal.com

🌐 www.rymbal.com